目录

Achieving high efficiency and precision is critical in today’s manufacturing and packaging industries. A bottle rinsing machine plays a pivotal role in achieving both. Whether filling beverages, pharmaceuticals, or cleaning products, a bottle rinsing machine is an indispensable part of the production line. It not only ensures product quality but also optimizes the entire automatic filling line process.

What is a Bottle Rinsing Machine?

A bottle rinsing machine is designed to clean bottles internally, using high-pressure water or air for a thorough wash. This step is crucial for ensuring that the product inside is not contaminated, which could affect its quality.

Bottle rinsing machines are usually part of an integrated automatic filling line, which consists of a series of automated systems that handle various tasks such as rinsing, filling, capping, and labeling. By automating these steps, manufacturers can increase production speed, reduce human error, and improve overall efficiency.

Why is Bottle Rinsing Crucial in the Filling Process?

Before filling any product into bottles, they must be thoroughly rinsed. Here’s why bottle rinsing is so important in the filling process:

- Prevent Contamination: Any remaining dust, dirt, or chemicals inside the bottle can contaminate the product, compromising its safety and quality.

- Improve Product Quality: A clean bottle ensures that the product remains uncontaminated, maintaining its purity and quality. This is especially critical in industries such as food and beverage, pharmaceuticals, and cosmetics.

- Ensure Consistency: An automated bottle rinsing machine ensures that every bottle is rinsed the same way, improving the consistency of the final product. This is crucial for consumer satisfaction and regulatory compliance.

- Increase Production Speed: Automatic rinsing machines are designed to operate at high speeds, enabling the continuous rinsing of large batches of bottles. This ensures a smooth and efficient production process.

Types of Bottle Rinsing Machines

There are various types of bottle rinsing machines, with the selection based on the specific requirements of the production line. Common types include:

- Air Rinsing Machines: These use high-pressure air jets to blow out dust and other contaminants from the bottle. They are commonly used for lightweight bottles and in industries that require minimal water consumption.

- Water Rinsing Machines: These machines use high-pressure water to clean the interior of bottles. They are commonly used in beverage bottling industries where water is a safe cleaning medium.

- Sterilization Rinsing Machines: Some bottles, especially in pharmaceutical or cosmetic industries, require sterilization before filling. These machines use hot water or steam to sterilize the bottles, ensuring they are free of bacteria or pathogens.

- Rotary Rinsing Machines: Ideal for high-volume lines, bottles rotate on a conveyor for complete cleaning.

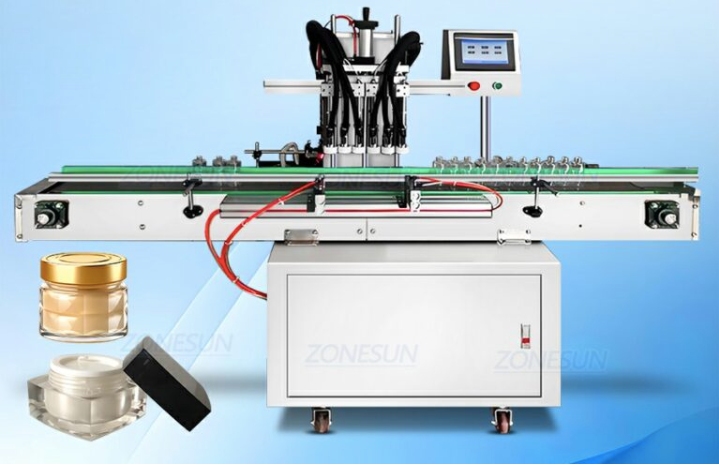

Bottle Rinsing Machines in Automatic Filling Lines

On an automatic filling line, the bottle rinsing machine is usually the initial step in the production workflow. Here’s a typical workflow:

- Bottle Loading: Bottles enter the machine via conveyor in the correct orientation for rinsing.

- Rinsing Process: Depending on the type of machine, bottles are rinsed with air, high-pressure water, or a combination of both. High-pressure systems ensure that bottles are thoroughly cleaned inside and out.

- Drying: After rinsing, some machines include drying mechanisms (such as compressed air or heat) to ensure that the bottles are dry before they move on to the next stage of the production line.

- Filling: Once the bottles are clean and dry, they are sent to the filling station, where the desired product is filled into each bottle. This could be liquid, powder, or paste, depending on the industry.

- Capping and Labeling: After filling, the bottles are capped and labeled before being packaged for distribution.

Benefits of Integrating a Bottle Rinsing Machine into Your Automatic Filling Line

- Enhanced Efficiency: Automatic rinsing machines significantly increase production speed, allowing businesses to handle large batches of bottles with minimal manual intervention.

- Consistency and Precision: Automation reduces human error, ensuring that every bottle is cleaned to the same standard. This is key for product quality and regulatory compliance.

- Cost Savings: While the initial investment in an automatic rinsing machine may be high, long-term savings from increased productivity and reduced waste can be substantial.

- Improved Hygiene and Safety: Automated rinsing eliminates contaminants from bottles, minimizing the risk of spoilage or contamination.

- Scalability: As production demands grow, automated systems like bottle rinsing machines can be easily scaled up to meet higher output without sacrificing quality.

Conclusion

A bottle rinsing machine is an essential component of an automatic filling line, ensuring that bottles are clean, dry, and ready for filling without the risk of contamination. Whether you’re in the food and beverage, pharmaceuticals, or cosmetics industry, investing in a high-quality rinsing machine can lead to improved product quality, faster production speeds, and cost-effective operations. By automating the rinsing process, you can achieve a more streamlined, efficient, and consistent production line, ultimately enhancing your product’s success in the marketplace.

If you’re considering adding a bottle rinsing machine to your production line, make sure to select one that matches your production needs, meets hygiene standards, and integrates seamlessly with your existing filling equipment.

0