目录

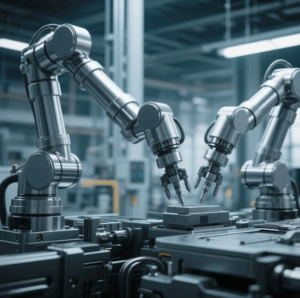

In the world of industrial automation, the 3 axis robot arm plays a vital role in improving productivity, consistency, and operational efficiency. As one of the most widely used robotic systems, this type of robot arm operates on three degrees of freedom, typically moving along the X, Y, and Z axes. Its simple structure and versatile capabilities make it ideal for a range of manufacturing tasks, from material handling to machine tending.

What Is a 3 Axis Robot Arm?

A 3 axis robot arm is a mechanical device that moves in three linear directions—left to right (X-axis), forward to backward (Y-axis), and up and down (Z-axis). Unlike more complex robotic systems with 4, 5, or even 6 axes, the 3 axis design focuses on tasks that do not require rotational motion or multi-directional articulation. This simplicity translates into lower costs, easier programming, and more stable performance in repetitive tasks.

Common Applications

One of the main advantages of the 3 axis robot arm is its ability to perform precise and repetitive operations. It is commonly used in:

- CNC Machine Tending: Automating the loading and unloading of workpieces to increase production speed.

- Pick and Place Operations: Accurately transferring items from one location to another in assembly lines.

- 3D Printing and Additive Manufacturing: Providing stable and controlled movement in the creation of objects.

- Laser Engraving or Cutting: Ensuring consistent motion across flat surfaces for high-quality results.

These applications demonstrate the practicality of the 3 axis robot arm in settings where flexibility is less important than accuracy and reliability.

Key Benefits

The popularity of the 3 axis robot arm in small to medium-sized enterprises stems from its practical advantages:

- Cost-Effective: With fewer moving parts and simpler control systems, it is more affordable than multi-axis alternatives.

- Ease of Maintenance: Simpler mechanics result in fewer potential points of failure.

- User-Friendly Operation: Easier to program and integrate into existing workflows, even for operators with limited robotics experience.

- Compact Design: Ideal for workspaces with limited room.

Limitations and Considerations

While the 3 axis robot arm offers many benefits, it’s important to note its limitations. It cannot perform complex movements such as rotating or twisting, which are essential in some advanced manufacturing applications. For tasks that require higher degrees of freedom, a 5 or 6 axis robot may be more suitable. However, for standardized, repetitive jobs, the 3 axis solution remains highly effective.

Conclusion

The 3 axis robot arm continues to be a reliable choice for industries seeking efficient and cost-effective automation. Its straightforward design and high precision make it an excellent option for a wide variety of industrial and commercial applications. As automation continues to evolve, this type of robotic arm will likely remain a cornerstone of modern production environments.

0